Cleaning after hardening

Axles and other machine components are often hardened.

The components must be cleaned after hardening.

This machine can be used to clean cylindrical parts, such as axles. After hardening, they are blast cleaned before the final grinding. The machine operates automatically. During blast cleaning, the axle rotates and the nozzles move above the axle.

Blast cleaning of axle ends

This machine uses a logic controlled blast cleaning machine to clean the ends of the axles. The blast cleaning is done using two nozzles with programmable movements.

The user selects the desired programme from the touch screen, and the machine performs the blast cleaning automatically.

Blast cleaning for hydraulic cylinders

Long hydraulic cylinders are blast cleaned using an 8-metre blasting cabinet. The cylinders are placed on the dolly outside the cabinet, and the dolly is moved inside.

The blasting takes place inside an enclosed chamber.The machine can also be used to clean products that are over 8 metres long by using special equipment.

Blast cleaning the frames of large machines

The frames of large machines that cannot fit inside the blast cleaning cabinet are blast cleaned in a blast cleaning room. The room and its equipment are dimensioned according to the customer’s needs.

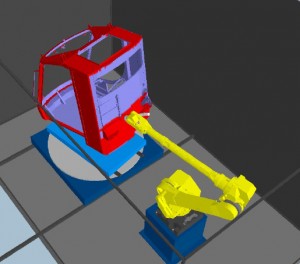

If the need for capacity is large, a manipulator or robot may be used in the blast cleaning.