Benefits of the Finnblast blast cleaning rooms:

- Reliable blast cleaning equipment

- Reliable blasting medium recycling equipment that has a high tolerance for impurities

- Low floor structure that reduces foundation costs

- Good visibility due to effective dust removal and bright lighting

- Effective removal of impurities from the blasting medium using a vibrating screen and airflow separator.

The Finnblast blast cleaning rooms consist of the following components:

- Sound-insulating room with a steel frame, built from sandwich panels

- Computer simulated dust removal

- Low floor with scraper conveyor to collect the blasting media

- Bucket elevator

- Airflow separator with vibrating screen

- Silo for blasting media

- Blasting pot

- Ventilation equipment

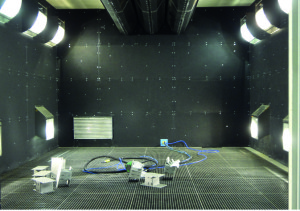

1. Blast cleaning room

The blast cleaning room has a steel frame. A thick sandwich element is placed inside the steel frame. This makes for a sealed room structure. The structure provides good sound-proofing; noise level outside the room is below 80 dB(A). The room can be fitted with doors at both ends, allowing for pieces to be transported through it. Pieces can be transported into the room using an overhead conveyor, dollies on rails or a forklift.

2. Dust removal from the blast cleaning room

Good visibility during blasting is one of the most important factors affecting productivity. When the visibility is good, the blaster can see which surfaces of the piece are already clean and which still require blasting. When visibility is good, the surfaces of the piece do not need to be blasted over and over again.

Two main factors affect visibility:

– The efficiency of dust removal

– Lighting

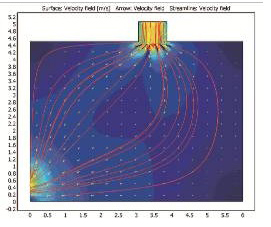

The efficiency of dust removal in Finnblast’s blast cleaning rooms is maximised by designing air flow and dust removal individually for each room. Below, you will find two simulated images that demonstrate how computerised flow design (CFD) can be used to dramatically improve dust removal.

For lighting, we use dust-proof lamp fixtures protected against wear. The number and intensity of the lamps is customised for each customer in order to ensure good visibility even during blast cleaning.

Air flow control guide vanes in the air intake duct. Consistent dust removal inside the entire room.

No guide vanes in the air intake duct. As a result, vortices with dust in the corners reduce visibility.

3. Floor with scraper conveyor

Over the decades, we have found the scraper conveyor floor to be a cost-effective and durable solution. The structure is based on a dolly that moves back and forth between the U steel profiles; the dolly is equipped with scrapers to move the blasting medium. The scraper dolly moves on top of maintenance-free rollers that are protected against the effects of the blasting medium.

Rubber profiles attached to the scrapers move the blasting medium forward. As the scrapers move forward, they carry the blasting medium with them.

4. Bucket elevator

The scraper conveyor carries the blasting medium to the bucket elevator located outside the blasting room. Here, the blasting medium is lifted onto the vibrating screen and airflow separator using an elevator.

5. Vibrating screen/airflow separator

The purity of the blasting medium is important in terms of productivity. The blasting medium that exits the blast cleaning room contains both coarse impurities and fine dust. A vibrating screen is used to remove coarse, large impurities from the blasting medium. An airflow separator is used to remove fine dust from the blasting medium. The dust is vacuumed into the filter.

6. Silo for blasting media

The clean blasting medium flows into the blasting media silo from the air flow separator. The size of the silo, the number of outlets etc. are determined by the application.

7. Blasting pot

The size of the blasting pot can vary between customers. The most common size for the blasting pot is 200 l. Several blasting pots are required when more blasters work in the room simultaneously.

Finnblast’s blasting pots are equipped with reliable, high-quality blasting medium valves. The valves are sleeve-type, making them easy to adjust and tolerant of impurities and disturbances.

8. Filter

The ventilation for the blast cleaning rooms is dimensioned to ensure good visibility during blast cleaning. The dusty air from the room is extracted into a filter. The filters are cartridge-type and have an automatic cartridge cleaning system. The filter separates the dust from the flowing air, and the fresh air is released into the surrounding hall area. Some of it is returned into the blast cleaning room. Dust accumulates into a dust bin located below the filter. A forklift can be used to empty the dust bin, for example.

9. Interior surface protection for blasting rooms

The interior surfaces of blasting rooms are subjected to harsh wear. Shot may travel at speeds of up to 200 m/s when it leaves the nozzle. Bouncing of the surface of the blasted surface slows down the shot, but it still moves very quickly. This is why the walls, and often the ceiling as well, need to be protected against the wear caused by the blasting spray and ricochet.

10. Lighting

Lighting is an important productivity factor for a blast cleaning room. We provide a sufficient number of lights to maintain bright illumination even when the room is operating at full capacity. We use dust-proofed metal halide lamps for lighting the blast cleaning rooms. The lamps are protected by a separate protective mesh that prevents the medium from hitting the lamp.