District heating pipe manufacturing

District heating pipes consist of thermal insulation on top of a steel pipe, and a plastic tube on top of the thermal insulation.

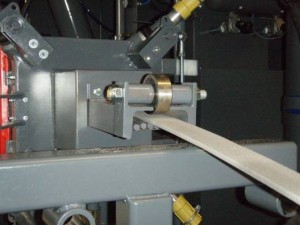

Blast cleaning of the steel pipe is important in order for the insulation to stay in place.

Finnblast offers a wide selection of compressed air machines and wheel blasting machines for the blast cleaning of pipes.

Factors affecting machine type selection include pipe diameters and capacity requirements, for example.

The blast cleaning machine can be equipped with automatic pipe loading and extraction equipment.

Steam boiler manufacturing

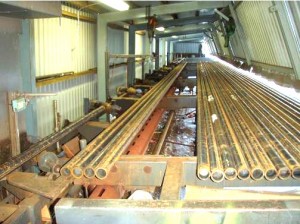

The walls of steam boilers are manufactured from panels consisting of flat steel and pipes that are joined together.

For welding, the flat steel pieces and pipes are blast cleaned, which allows for increasing the welding speed and reducing the number of welding errors.

This increases welding productivity and product quality.

Finnblast offers machines for blast cleaning flat steel as well as pipes.

The blast cleaning machines can be installed as part of an automatic panel production line.

Capacitor manufacturing

Capacitors are used for reactive-power compensation and filtering of harmonic components in electrical networks. Capacitors have metal cases that are subjected to weather conditions. Anti-corrosion treatments and painting can increase the service lifetime of the protective case and, subsequently, the capacitor itself. For painting, the case must be cleaned and roughened in order to increase its tolerance of environmental stress. High-quality anti-corrosive coating is especially important when capacitors are placed in a maritime climate or otherwise difficult environmental conditions.

Capacitors are blast cleaned using a drive-through type roller conveyor machine. Capacitors of different sizes can enter the machine in random order. The size of the capacitors is measured at the entrance, and the blast cleaning process is adjusted accordingly.